Our Manufacturing Capabilities Make the Difference

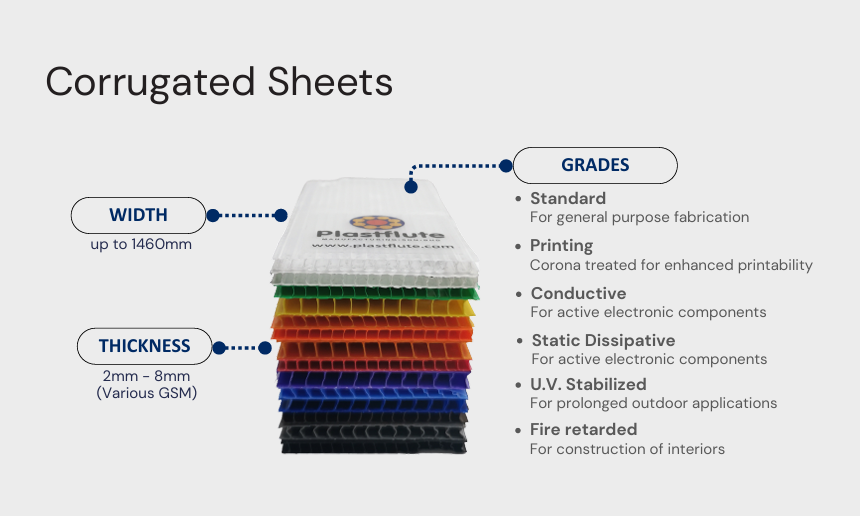

Our manufacturing plant is currently equipped to extrude up to 3 metric tons of corrugated polypropylene sheets per day. We are capable of producing sheets with widths up to 1500 mm and thicknesses ranging from 2 mm to 8 mm.

Grades Available

General, Corona Treated, Anti-Static, Conductive, UV Stabilized, and Flame-Retardant grades are available to meet specific performance requirements.

Processing Techniques

- CNC prototyping

- Ultrasonic welding

- Induction welding

- Steel rod welding

- Edge sealing

Forming Process

- Slitting

- Folding

- Creasing

- Foam cutting

- Sheet spooling

- CAD 2D cutting

- 3D conceptualization

Printing

- Silk screen printing

Resource Recovery

- Granulation of sheet products

- Re-use of recycled sheets

- Re-compounding of polypropylene

One-Stop, From Extrusion to Solutions

Plastflute extrudes copolymer polypropylene (PP), electro-static dissipated PP, antistatic PP, UV stabilized PP, fire-retardant PP, and other specialty compounds.

Polypropylene PP sheets and boards are widely used in packaging, advertising, construction, agriculture, industrial, and pharmaceutical applications.

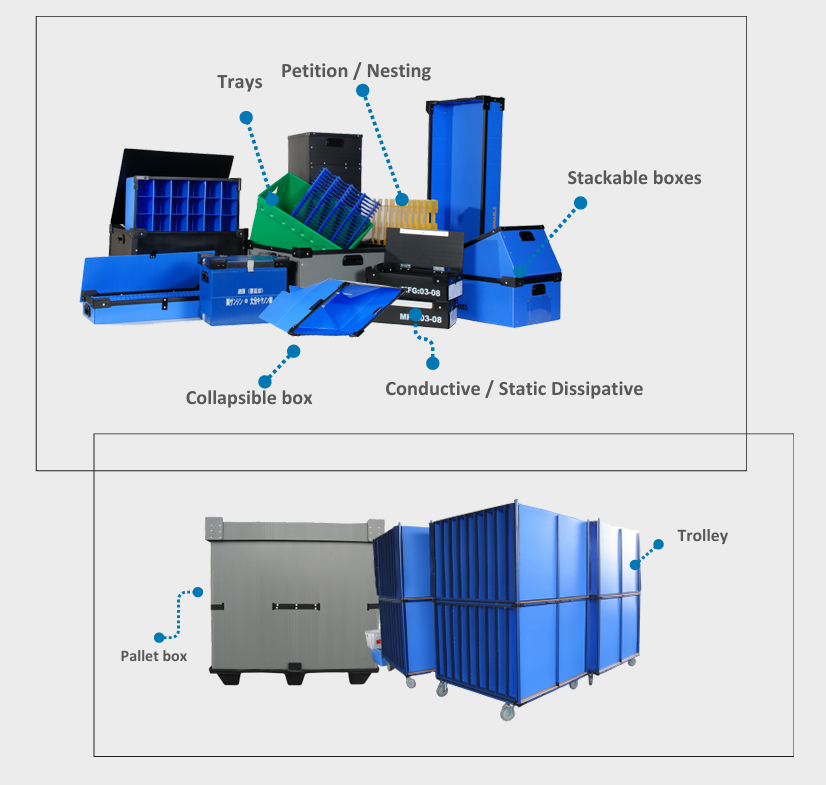

Plastflute also custom designs and manufactures boxes and trays to meet customers’ special requirements.

View Product Page